The manufacturing sector is undergoing a significant makeover driven by artificial intelligence (AI) and machine learning (ML). Once considered a sector driven only by manual labour and mechanical automation, manufacturing has evolved into a data-powered, intelligent ecosystem. Thanks to artificial intelligence and machine learning, manufacturers are reaching ever-greater efficiency, productivity, and scale of invention.

In this blog, we will discuss the primary technologies driving artificial intelligence and machine learning in manufacturing, showcase actual use cases, and go over the obvious benefits businesses are realising with these changing tools in this blog article.

Understanding AI & ML in Manufacturing

Artificial intelligence (AI) is the power of machines to duplicate human intelligence, including natural language processing, decision-making, and capacity for problem-solving ability. Part of artificial intelligence, machine learning (ML) allows machines to learn from data without explicit programming, hence improving performance over time via continuous learning.

Examining enormous volumes of manufacturing-related tools, sensors, and equipment, artificial intelligence and machine learning technologies predict outcomes, simplify processes, reduce errors, and support data-driven decision-making.

Essential Manufacturing AI and ML Technologies

Predictive Analytics & Maintenance

- ML systems can project possible mistakes before they happen by examining past machine data.

- Early on problem addressing by predictive maintenance helps to reduce maintenance costs and downtime.

Visual Computer Vision

- Applied for quality control and defect discovery visual inspections.

- Human inspection is replaced by real-time, far more accurate product analysis made feasible by cameras connected with artificial intelligence models.

Digital Twins

- A digital twin is a virtual replica of a physical object or process.

- Driven by artificial intelligence and machine learning, digital twins copy factory settings to maximise performance and test new ideas without impacting real-time operations.

Robotics and Automaton

- Extremely accurate handling of challenging manufacturing tasks including assembly, material handling by AI-powered robots, and welding

- Working with human staff, collaborative robots—also called cobots—boost safety and output.

Natural language processing (NLP)

Allows robots to grasp and respond to human language, therefore enabling automaton of report generating, voice-command interfaces, and troubleshooting.

Edge Computer in IoT Integration

- Smart sensor and Internet of Things (IoT) device real-time data collection from machinery and production lines

- Run on edge devices; ML models provide fast insights free from dependability on cloud latency.

Manufacturing Real-World Use Cases of AI and ML

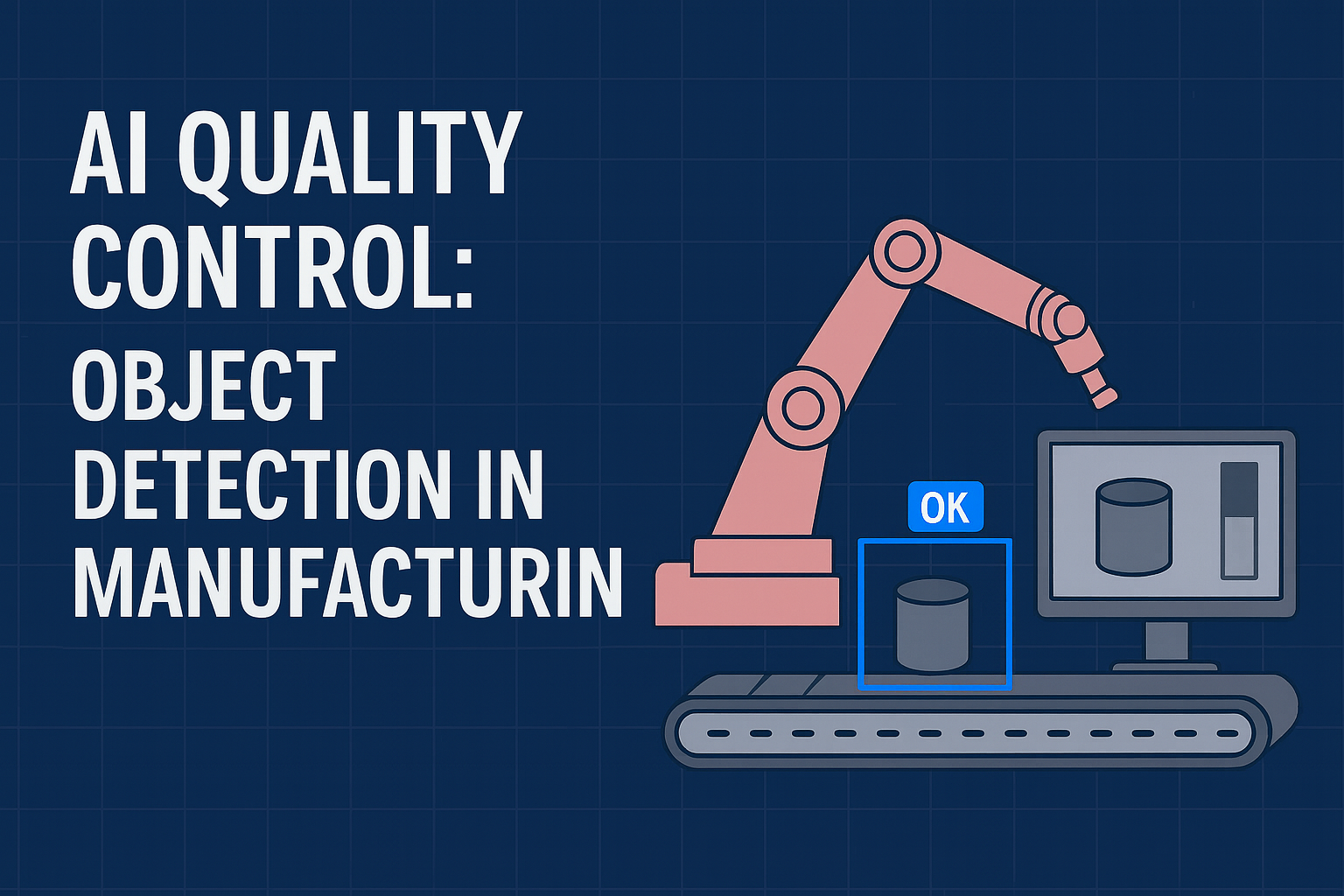

1. Intelligent Control of Quality

Conventional quality controls are prone to human errors and take time. Every minute, thousands of images let AI-powered computer vision systems detect anomalies and defects. ML models might be used, for example, by an automotive company to identify assembly line paint defects or misalignments.

2. Maintenance Predictive Approach

Among the most costly issues facing production are downtime. Companies like Siemens and GE can foresee when a part is likely to break using AI-powered predictive maintenance tracking of vibration, temperature, and other sensor data, therefore enabling planned repair and lowering of production disruptions.

3. Improving Supply Chains

ML methods are used by manufacturers to control logistics, project demand, and inventory. Examining prior sales data, seasonal trends, and outside variables like weather or geopolitical events allows AI to create precise demand planning and improve delivery times.

4. Enhancement Process

Artificial intelligence can improve workflow, reduce energy consumption, and decrease waste using industrial data analysis. Artificial intelligence might alter mixing speed and temperature depending on data trends in chemical manufacture, for example, to increase yield and uniformity.

5. Labour Safety and Effectiveness

Track workers' motions using wearable gadgets and computer vision monitors to alert them of hazards or improper lifting techniques. Artificial intelligence also facilitates job organisation and management depending on workers' skill levels and availability, therefore improving production and safety.

Manufacturing Benefits from AI and ML

1. Improved Functional Performance

Artificial intelligence streamlines manufacturing processes by means of inefficiencies eliminated. Automated decision-making and real-time optimisation help businesses to ensure constant product quality while reducing cycle times.

2. Cost Cutting Strategies

Predictive maintenance, waste minimisation, and optimum utilisation of resources follow in major cost savings. Manufacturers can stop unnecessary inventory building, reduce downtime, and decrease overproduction.

3. Enhanced Goods Quality

AI ensures that continually observing the manufacturing process and identifying anomalies helps to regularly satisfy quality standards. This enhances brand recognition and helps to reduce the defective goods count.

4. Faster Time-to- Market

Prototyping, real-time testing, and artificial intelligence-enabled simulations enable faster creation and introduction of new goods. This gives producers a competitive edge in response to consumer needs.

5. Data-Driven Choice Making

Artificial intelligence turns raw data into insights worth using. Plant managers and executives can make better decisions using real-time analytics, predictions, and simulations than by depending just on gut feeling or outdated data.

6. Improved Flexibility

Artificial intelligence supports mass customising by allowing manufacturers to modify production runs for numerous product variants with the least impact. Particularly in industries including electronics and consumer goods, this is rather important.

Difficulties Using AI and ML in Manufacturing

Though the benefits are convincing, execution is not without challenges:

- Integration spanning data silos: Many times missing compatibility, legacy systems complicate data consolidation.

- Skilled Gap: Demand is for skilled professionals without the capacity to design and maintain artificial intelligence/machine learning systems in manufacturing.

- ROI and cost issues: Initial setup costs could be high, so assessing ROI in near term can be difficult.

- Personal Privacy and Security: Strong cybersecurity methods are necessary for given higher possibility of cyberattacks resulting from increasing connectivity.

By means of gradual adoption, agreements with artificial intelligence solution providers, and workforce development initiatives, many firms are overcoming challenges in spite of these constraints.

Future Developments in Manufacturing

- Hyper-Automation: artificial intelligence and machine learning Future artificial intelligence and machine learning trends will be shaped by combining artificial intelligence, machine learning, RPA (robotic process automation), and IoT for totally automated production environments.

- Cloud-based AI systems, or AI-as-a- Service (AIaaS), will enable smaller manufacturers to leverage advanced analytics without a significant outlay of money.

- Self-healing machines—AI-powered gadgets capable of independently spotting and fixing errors—are not too far off.

- Sustainable Manufacturing: Maximising energy use, reducing emissions, and improving supply chain transparency for sustainability goals will all depend on artificial intelligence significantly.

In Conclusion

Artificial intelligence and machine learning are not just buzzwords in manufacturing; they are powerful tools that are transforming the processes of manufacturing, inspection, and product delivery. The impact is transformative from predictive maintenance and quality control to supply chain optimisation and smart automation.

Early adopters of AI and ML development technologies will position themselves for long-term success in a globally competitive and constantly changing environment. Even if the route may demand strategic investment and planning, the advantages—greater efficiency, cost savings, innovation, and agility—far exceed any difficulties.

As technology advances, manufacturing will get smarter, safer, and more sustainable, driven by smart equipment and smart data.

Leave a reply